MIL-DTL-40082C

2.3 Order of precedence. In the event of a conflict between the text of this document and

the references cited herein, the text of this document takes precedence. Nothing in this

document, however, supersedes applicable laws and regulations unless a specific exemption

has been obtained.

3. REQUIREMENTS

3.1 Design. The heraldic design of the hub or die shall be transferred by reducing

device from the Government-loaned drawing or sculpted model to the size specified in the

procurement document (see 6.2). When an existing hub or die is used for manufacturing

purposes, the heraldic design of the new hub or die shall be an exact replica of the

Government-loaned hub or die.

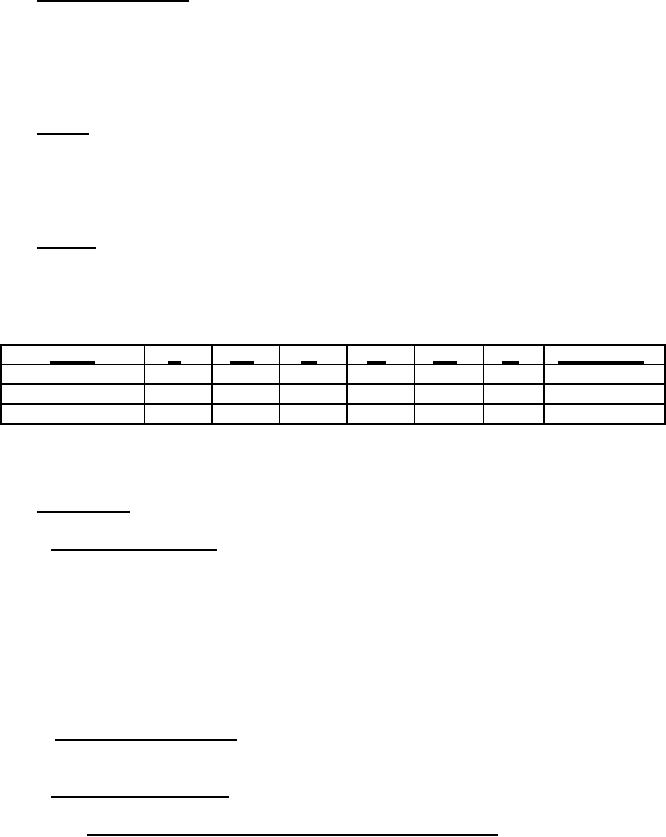

3.2 Material. Material for hubs and dies shall be alloy tool steel conforming to S7 or L6

of ASTM-A681. (For verification, see 4.2.1.) Typical composition is shown in Table I. The

use of any other steel shall not be permitted under this specification.

TABLE I. Steels and their typical composition.

C*

Mn*

Si*

Cr*

Mo*

Ni*

Remainder*

Name

S7

0.50

0.75

0.25

3.25

1.40

--

Fe

L6

0.70

0.60

0.25

0.70

--

1.40

Fe

* carbon (C), manganese (Mn), silicon (Si), chromium (Cr), molybedenum (Mo),

nickel (Ni), and iron (Fe)

3.3 Construction.

3.3.1 Sizes of hubs and dies. The minimum height of hubs and dies shall be 2 inches

for heraldic designs under 4 inches in length, width, or diameter. The minimum height of

hubs and dies for heraldic designs 4 inches and over in length, width, or diameter shall be

2-1/2 inches. The width, length, or diameter of any hub shall provide a minimum of 3/8 inch

clearance between the outside edge of the design and the edge of the hub. The length,

width, or diameter of any die shall provide a minimum of 1/2 inch clearance between the

outside edge of the design and the edge of the die. There shall be sufficient cutaway or

relieved area around the embossing on each hub (driving area) to insure penetration past

the embossed design when driving the hub into the working die.

3.3.2. Shapes of hubs and dies. Unless otherwise specified (see 6.2), the shape of the

hubs and dies shall be round, square, or rectangular.

3.3.3 Cutting of hubs and dies.

3.3.3.1 Cutting of hubs and dies for items with no enamel/epoxy. For designs with

outer rims, hubs and dies for items requiring no enamel or epoxy shall be cut with a

minimum depth of 0.030 inch from the top of the design to the bottom of the design. For

designs without outer rims, hubs and dies requiring enamel shall be cut with a minimum

depth of 0.020 inch from the top of the design to the bottom of the design. The height or

depth of modeled areas or detail lines shall be determined by the tool-maker as appropriate

for the individual design of the heraldic item. Design walls shall be cut with a cutting tool

2

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business