MIL-DTL-15665J

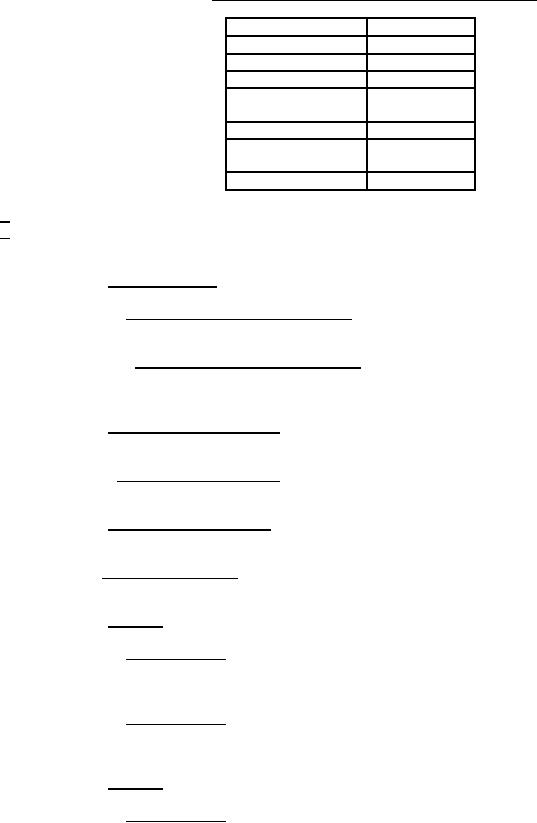

chemical composition of the copper content of the copper base alloy shall

be as specified in Table I.

TABLE I.

Copper content of copper base alloys.

ALLOY

COPPER

Yellow Brass

64.0-68.5

Red Brass

84.0-86.0

Gilding Metal

94.0-96.0

Free Cutting

60.0-63.0

Brass

Bronze

89.0-91.0

Nickel Silver

63.0-65.5

1/, 2/

Low Brass

78.5-81.5

1/ Copper content for the nickel silver pin only may be 53.6 to 56.5%.

2/ When nickel silver is used as a base material, the nickel content shall

be not less than 18%.

3.4.2

Gold plating.

3.4.2.1

24 karat gold for plating.

Gold for plating shall be 24

karat.

3.4.2.2. 22 karat gold for plating. When specified on the

applicable specification sheet, gold for manufacturing insignia with

nickel underplating shall be 22 karat.

3.4.3 Zinc aluminum alloy. The alloy used for die casting shall

conform to alloy AG 40a or AC 41a of ASTM-B-86.

3.4.4. Nickel for plating. Nickel for plating shall be the nickel

plating normally used in commercial practice.

3.4.5 Silver for plating.

Silver for plating shall be not less than

99.5 percent pure silver.

Rhodium Plating. Rhodium for plating shall be the rhodium

3.4.6

plating normally used in commercial practice.

3.4.7

Solder.

3.4.7.1 Hard Solder. Hard solder shall be a silver alloy solder

having a melting point of not less than 1075 degrees Fahrenheit (561.7

degrees Celsius).

3.4.7.2 Soft Solder. Soft solder shall be a lead-tin alloy having a

melting point of not less than 375 degrees Fahrenheit (190.58 degrees

Celsius).

3.4.8

Enamel.

All enamel shall be lead free.

3.4.8.1 Hard enamel. Hard enamel shall be a glass, vitreous type

enamel fused with metallic oxides to produce the required color, opacity

or translucence and shade.

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business