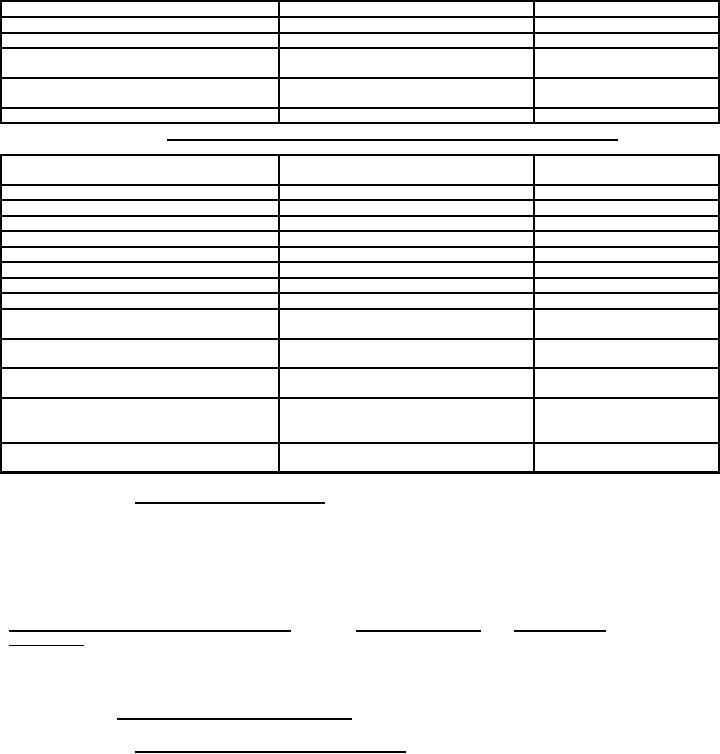

MIL-DTL-15665J

PARAGRAPH

Copper base alloy

Material

identification

3.4.1

Zinc aluminum alloy

Material

identification

3.4.3

24 karat gold plating

Material

identification and

3.4.2.1

karat

22 karat gold plating

Material

identification and

3.4.2.2

karat

Nickel for plating

Material

identification

3.4.4

Table II.

Contractor's certificate of compliance (Continued)

Silver for plating

Material

identification and

3.4.5

fineness

Rhodium plating

Material

identification

3.4.6

Hard solder

Material

identification

3.4.7.1

Soft solder

Material

identification

3.4.7.2

Hard enamel

Material

identification

3.4.8.1

Soft enamel

Material

identification

3.4.8.4

Epoxy resin

Material

identification

3.4.8.2

Baking enamel

Material

identification

3.4.8.3

Lacquer

Material

identification

3.4.9

Brass for prongs (when

Material

identification

3.6.5.5

applicable)

Nickel silver for prong

Material identification

3.6.5.1 and 3.5.6.4

(when applicable)

Brass for screw post &

Material Identification

3.6.5.3

thumb nut

Brass for washer (Marine

Material identification

As specified on

Corps only)

applicable

specification sheet

Back Plate (Army branch of

Material identification and

3.6.5.5

service insignia)

temper

4.4.1.2 In-process inspection. In process inspection shall be made

at any point or during any phase of the manufacturing process to determine

whether operation or assemblies are accomplished as specified. The

Government reserves the right to exclude from consideration for acceptance

any material for which in-process inspection has indicated nonconformance.

In-process inspection shall be conducted to see that accomplished of the

following is in accordance with the specification requirements.

REQUIREMENT, OPERATION OR ASSEMBLY

CHARACTERISTICS

REQUIREMENT

PARAGRAPH

Black chemical finish

Used as a base

3.7.2.4

Nickel plating

Not used as an underplating

3.7.1.1

4.4.2

Inspection of the end item.

4.4.2.1 Visual examination of insignia. Visual examination of

insignia for defects in finish, design, material, construction,

workmanship and marking shall be made using Table II. Examination shall

be made at a distance of approximately 16 to 18 inches with illumination

equal to average daylight and arranged so as to avoid as much reflected

light as possible. Defects designated by an asterisk (*) shall be

classified a major when seriously affecting appearance or serviceability

and minor when affecting appearance or serviceability but not seriously.

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business