MIL-DTL-82112C(MC)

4.4.3 Examination of the end item. Prior to the formation of a

lot and as a final step in the contractors production control

plan, each item shall be examined for those defects listed in

4.4.3.1 and 4.4.3.2. The sample unit shall be one item.

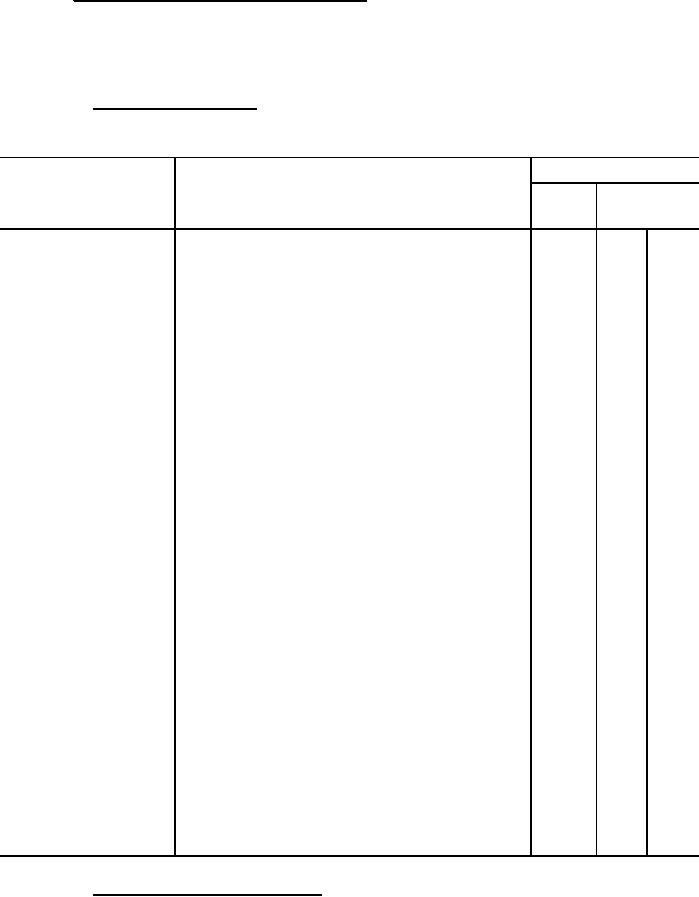

General defects shall be classified as

4.4.3.1. General defects.

follows:

Classification

Examine

Defects

Major

Minor

A

B

Material,

a. Any hole, cut, tear, float,

101

base cloth

broken pick, slub, stain,

streak, or other visible

defect.

Underlay,

a. Other than specified.

102

crinoline and

lining

Color or shade

a. Color or shade of any

103

component other than as

specified.

Buttons and

a. One or both omitted, wrong

201

ring fasteners type, style, class or color.

(when required)

Design

a. Any detail not conforming

202

to requirements or standard

sample.

Workmanship

a. Any component missing.

203

b. One or more embroidery

204

stitches missing or out of

alignment affecting appearance.

c. Rework damage, affecting

205

appearance.

d. Stitches per inch less than

301

specified.

Embroidery

a. Not as specified.

206

b. Core yarn not fully covered

207

with metallic ribbon.

c. Loose stitches.

208

4.4.3.2. Finished measurements. Any dimension exceeding the

tolerances specified below shall be classified as a defect:

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business