MIL-DTL-14645C

3.6 Tolerances. Unless otherwise specified herein or on the applicable drawing, dimensions

of the finished shoulder mark and its visible components shall be within a tolerance of ± 1/32

inch (see 4.3.3).

4. VERIFICATION

4.1 Classification of inspections. The inspection requirements specified herein are classified

as follows:

a. First article inspection. Inspection and testing of the first article (see 3.1) shall be

made of a completely finished item or items for all provisions of this specification applicable to

the end product examination and tests (see 4.3.2 and 4.3.3).

b. Conformance inspection. Inspection shall be in accordance with the provisions set

forth herein, except where otherwise indicated (see 6.2). Sampling for inspection shall be

performed in accordance with ANSI/ASQC Z1.4.

4.2 Inspection conditions. Unless otherwise stated, all inspections shall be performed in

accordance with the test conditions specified in 4.3.

4.3 Methods of inspection.

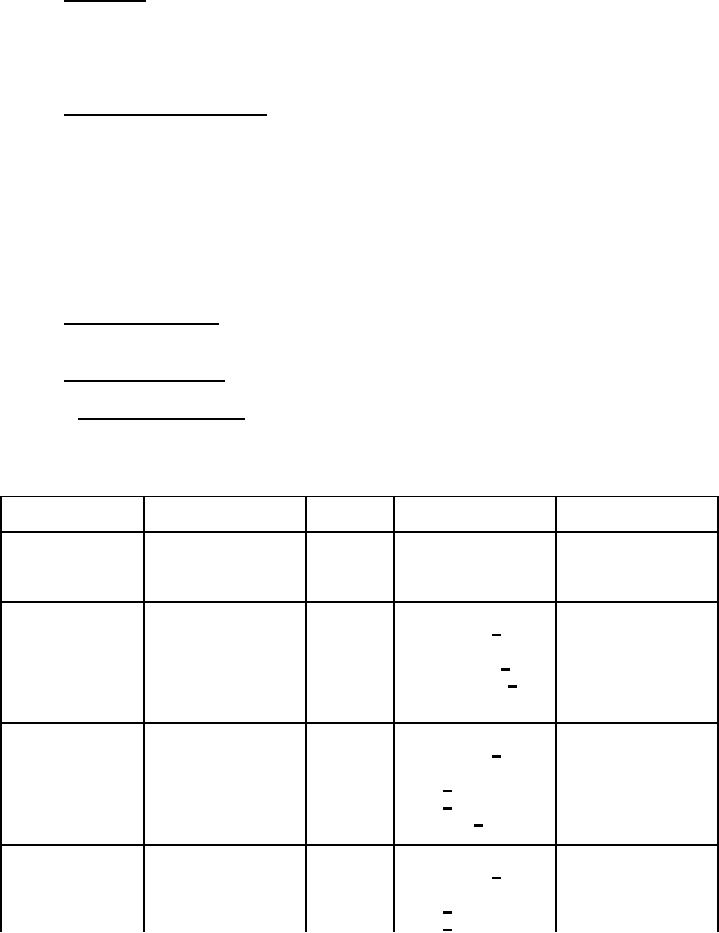

4.3.1 Testing of components. Except as otherwise stated in TABLE II, testing of

components shall be in accordance with the stated test method from FED-STD-191.

TABLE II. Testing of components.

RESULTS

COMPONENT

CHARACTERISTIC

RQM'T

TEST METHOD

REPORTED AS

Laminated cloth

bubbles/puckering

before & after wet

dry cleaning

3.3.1

visual

pass or fail

Fusible cloth

amount of adhesive

3.3.1.1

visual

pass or fail

ASTM-D276, 1/

material identification

3.3.1.1

pass or fail

weave

3.3.1.1

visual

pass or fail

ASTM-D3776, 1/

weight

3.3.1.1

nearest 0.1 oz/sq yd

AATCC-96, Vc, 1/

shrinkage

3.3.1.1

nearest 0.1 % in each

direction

Polyester/wool

ASTM-D276, 1/

shell fabric

material identification

3.3.1.2

pass or fail

colorfastness to:

5622, 1/

wet dry-cleaning

3.3.1.2

pass or fail

5662, 1/

light

3.3.1.2

pass or fail

AATCC-8, 1/

crocking

3.3.1.2

pass or fail

Textured poly-

ASTM-D276, 1/

pass or fail

ester shell fabric

material identification

3.3.1.3

colorfastness to:

5622, 1/

wet dry-cleaning

3.3.1.3

pass or fail

5662, 1/

light

3.3.1.3

pass or fail

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business