MIL-DTL-14645C

3.5.1 Embroidery. The device(s) and stripe(s) for each class of shoulder mark shall be

Schiffli or Multihead embroidered on the face side of the shell fabric. The embroidery stitches

shall be of the type, color (see DOD Standard Shades for Heraldic Yarns for Embroidery and

Ribbons), length, minimum number, and density specified by the applicable cartoon. Yarn

specified in 3.3.3.1 and 3.3.3.2 shall be used as shown in TABLE I.

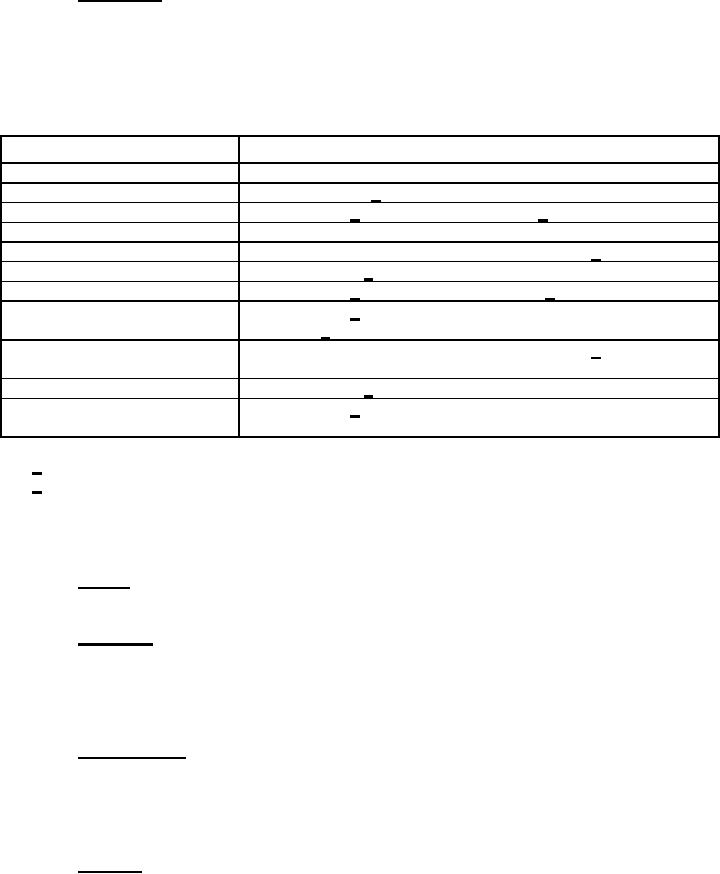

TABLE I. Use of embroidery yarns.

TYPE, CLASS

YARN(S) USED

Type I:

all silver metallic 1/

Classes 1 thru 6, 8, and 9

silver metallic 1/ for stripe; gold metallic 2/ for device

Classes 7 & 10

Type II:

white rayon or polyester for stars; gold metallic 2/ for stripe

Classes 1 thru 4

all gold metallic 2/

Classes 7 & 10

silver metallic 1/ for device; gold metallic 2/ for stripe

Classes 5, 6, 8, & 9

silver metallic 1/ & black rayon or polyester for device; gold

Classes 11 thru 14, 16

metallic 2/ for stripe

white rayon or polyester for stars; gold metallic 2/ for eagle

Class 15

device & stripe

all gold metallic 2/

Type III:

silver metallic 1/ for device; graphite blue rayon or polyester

Type IV

for border stitch

1/ Silver metallic embroidery shall have an underlay of white rayon or polyester

2/ Gold metallic embroidery shall have an underlay of goldenlight rayon or polyester

Sufficient base cloth shall be allowed in all directions so shoulder marks can be properly

hemmed and joined together.

3.5.2 Cutting. After insignia have been embroidered, material shall be cut so that the

finished shoulder mark will conform to the measurements specified on the applicable drawing.

3.5.3 Hemming. The hemming shall be executed at the location indicated on the applicable

drawing or cartoon. Each hem shall have a minimum of 10 and a maximum of 12 stitches per

inch using a type 301 stitch of ASTM-D6193. All ends of stitching not caught in the seam shall

be backstitched a minimum of 1/4 inch. Hems shall be 3/8 inch + 1/8 - 0 inch wide, and

stitching shall be located 1/8 inch + 0 - 1/32 inch from the turned edge.

3.5.4 Seam stitching. Seam stitching shall be in accordance with Type 301 of ASTM

D-6193. All ends of stitching shall be backstitched not less than 1/4 inch. Thread breaks shall

be backstitched not less than 1/2 inch at each break. Thread tension shall be maintained

equally for top and bottom thread. Seams shall be sewn with not less than 10 and not more

than 12 stitches per inch. All thread ends shall be trimmed.

3.5.5 Pressing. The finished shoulder mark shall be turned and pressed so that the item

has the shape shown on the applicable drawing.

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business