MIL-DTL-3628/81C

SUSPENSION BAR:

OBVERSE: Epoxy resin (Stoning epoxy), 24K Gold Plated, Matte Finish, Polished

Highlights and shall match TIOH Metal Finish Chip Number 8.

REVERSE: 24K Gold Plated, Mirror-like Polish and shall match TIOH Metal Finish

Chip Number 6.

DIMENSIONS:

PENDANT:

HEIGHT (Overall): 1-1/2 inches (REF)

WIDTH (Overall): 1-5/16 inches (REF)

THICKNESS: (Edge): 0.100 inch + 0.010 inch

SUSPENSION BAR:

HEIGHT (Overall): 11/32 inch (REF)

WIDTH (Overall): 1-7/8 inches (REF)

THICKNESS (Edge): 0.075 inch + 0.010 inch

EPOXY: Epoxy resin shall be applied to the Badge Qualification as indicated above,

and shall match TIOH Hard Enamel Color Chip Numbers listed below. Hard cloisonné

enamel may be used in lieu of epoxy. If hard cloisonné enamel is used, the required

base material shall be Gilding Metal 95/5 (UNS Alloy C-210).

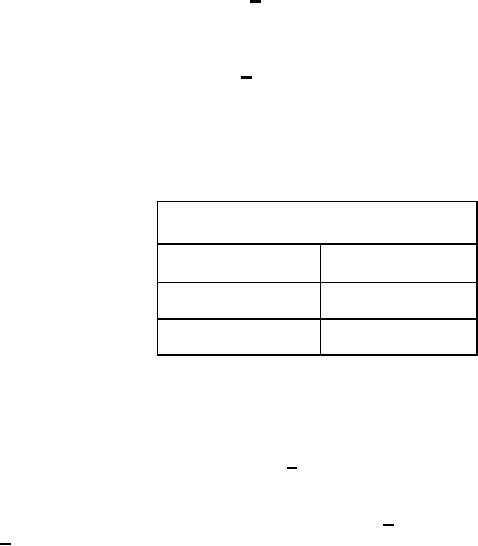

TIOH HARD ENAMEL COLOR

CHIPS

COLOR

CHIP NUMBER

Black

#26

White

#28

ATTACHING DEVICE AND LUGS:

1 The attaching device shall be prong and clutch type.

2. The prongs shall be located on the horizontal centerline of the suspense bar,

equidistant from each end and 1-1/2 inches + 1/32 inch apart.

3. The links shall be fabricated from gold plated wire with a nominal diameter of 0.050

inch. The overall dimension of the links shall be 1/4 inch + 1/64 inch in length and 7/32

inch + 1/64 inch in width.

4. All lugs are integral.

NOTE:

The term (REF) refers to the measurements taken from the Government furnished hub or die.

CHANGES FROM PREVIOUS ISSUE: Marginal notations are not used in this revision to

identify changes with respect to the previous issue due to the extent of the changes.

Page 2 of 3

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business