MIL-DTL-28964C

4.3.2 Examination of insignia for dimensions. Any dimension that is not within the

tolerances specified on Drawing Nos. 705002A0000 and 7lC5005A0000 shall be classified as

a defect.

4.3.3 Testing of the end item. The testing of the completely fabricated insignia shall be

performed in accordance with the following for the characteristics shown therein. There shall be

one determination per sample unit and results shall be reported as pass or fail. The sample unit

shall be seven pair completely fabricated insignia of each type and class. The requirements are

applicable to the individual unit. For the bending strength test, the sample unit shall be one item

and all prongs on that item will be tested. However, one defect will be scored regardless of how

many prongs fail on the item.

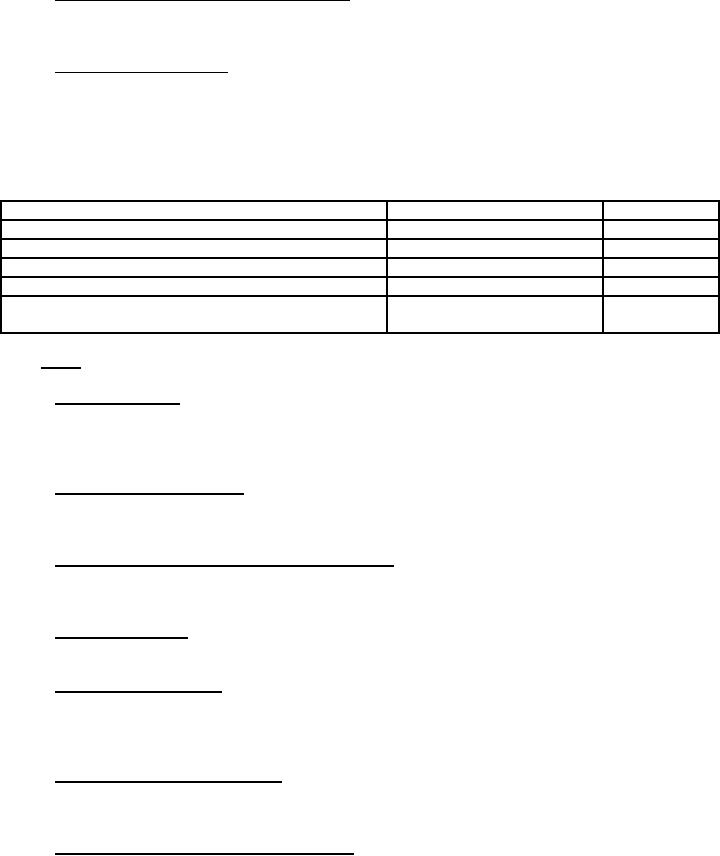

Characteristic

Requirement paragraph

Test method

Test for attaching device (clutches)

3.2.2

4.4.1

Test for nail strength for integral prongs.

3.2.2

4.4.7

Test for thickness

3.2.1.1

4.4.4

Test for micro-thickness

3.4.1

4.4.3

Test for bending strength and all the

3.2.2

4.4.2

requirements

4.4 Tests

4.4.1 Test for clutches. The clutch shall be removed and replaced ten times from the prong.

An attempt shall then be made to remove the clutch by hand without first depressing the release

wings, during which time the clutch and prong shall be inspected to determine compliance with

3.2.2.

4.4.2 Test for bending strength. The prongs shall be bent five times through a 90o angle, 45o

on each side of the prongs perpendicular position. Bending of the prongs shall be performed

slowly, and each bending action shall take 10 seconds.

4.4.3 Direct micro-thickness test for copper plating. The copper plating thickness shall be

determined in accordance with ASTM-E 498. The results shall be evaluated to determine

compliance with 3.4.1.

4.4.4 Test for thickness. The test shall be performed in accordance with ASTM-D 638. The

test shall be performed to determine compliance with 3.2.1.1.

4.4.5 Test for baked enamel. Draw a knife edge across the face side of the specimen making

four parallel scores one-sixteenth inch apart. Repeat this process, drawing the knife edge this

time perpendicular to the previously scored lines, making small blocks in the finish. The

finish shall then be examined to determine compliance with 3.4.1.

4.4.6 Acetone test for baked enamel. The enameled surface shall be wiped five times with a

piece of cotton saturated with acetone. The cotton shall be examined to determine compliance

with 3.4.1.

4.4.7 Test for nail strength for integral prongs. The insignia to be tested will be placed in a

jig which allows no movement of the insignia and positions prongs on a 30o degree angle

above the horizontal. A vertical 10 lb. load shall be applied to the top third position of each

prong. No evidence of breaking or cracking shall occur in compliance with 3.2.2.

5. PACKAGING

5

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business