MIL-DTL-14652B

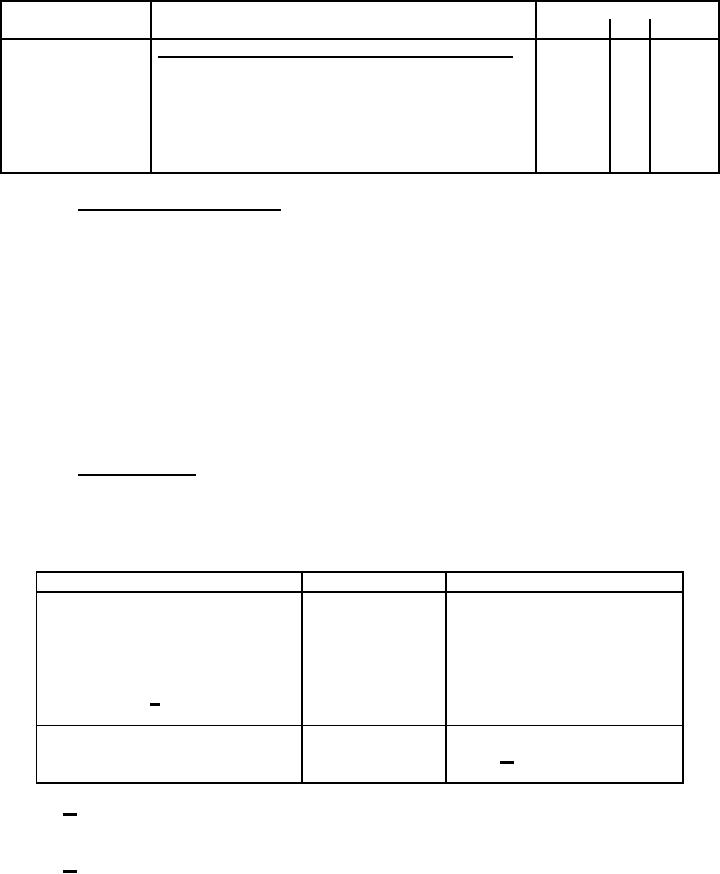

TABLE IV Visual examination of the end item. - Continued

EXAMINE

DEFECT

CLASSIFICATION

MAJOR

(T)

MINOR

Types II and III Base Cloth Borders and Edges

T

Not uniform in width or unevenly trimmed. . . . . . .

T

Corners or points not well defined. . . . . . . . . . . . .

Free material between edge of design and raw

X

edge of material not as specified. . . . . . . . . . . . .

W

Not cut in single units when required. . . . . . . . . . .

4.3.3 Examination for dimensions. Measurements shall be taken of all points, lines, areas,

curves, radii, and spaces for which dimensions are specified in the cartoon or drawing,

including:

Overall length

Overall width

Border width

Device location

Device dimension

Spaces and distances between intermediate points

Tolerances shall be as specified in 3.6. Any dimension that is not within the specified tolerance

shall be classified as a major defect.

4.3.4 End item testing. Except as otherwise stated in TABLE V, testing of the completely

finished item(s) shall be in accordance with FED-STD-191. "The completely finished item" is

defined as one insignia.

TABLE V. End item testing.

CHARACTERISTIC

RQM'T

TEST METHOD

Colorfastness of embroidery &

overedge stitching yarn to:

Wet-dry cleaning

3.3.1.4 & 3.3.3.3

5622

Light

3.3.1.4 & 3.3.3.3

AATCC-16, Option A

Laundering 1/

3.3.1.4 & 3.3.3.3

AATCC-61, Test 3A

Overedge stitching:

5052 2/

Stitches per inch

3.5.3.2

1/ Only the stain on the fiber of the color transfer cloth represented in the basic

materials being tested, shall be evaluated.

2/ The contractor shall furnish a certificate of compliance.

5. PACKAGING

13

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business